Inspecting Tube Ends

The MAC Solution

- Fulfills API 5CT & 5L

- Detects ID & OD longitudinal and transverse notches down to 5% of the tube wall

- Detects lamination 6.2mm FBH

- Measures wall thickness

- Innovative Automated

Pitch Control - Unique end plug cone follows unstraight tube ends

ends” must be cut off, resulting in a substantial loss of product and revenue, or the manufacturer needs to

develop a method to test these ends to meet the tube integrity requirement. Some industries require that the

end be tested to a higher level of integrity because it is being expanded, threaded, or welded in the field,

and end integrity is critical to the tube performance. MAC’s new UT End Tester provides a solution to this

problem.

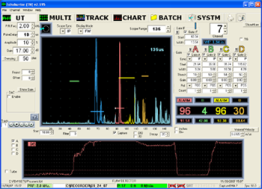

MAC’s Echomac FD-5 electronics provide the

critical software for controlling the transducers

and receiving, adjusting, analyzing, and

reporting the test results.

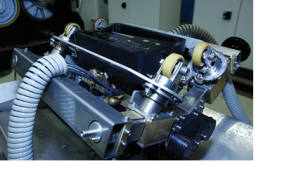

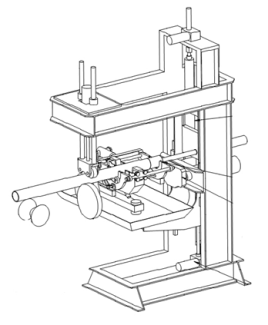

The Echomac® UT End Tester consists of two

The Echomac® UT End Tester consists of twoindependent, identical test stations designed to

inspect the untested portion of a tube end.

Generally this portion would range between 250

and 500mm from the tube end, depending on the

application.

DOWNLOAD Pdf

0 komentar:

Posting Komentar