Blogroll

-

VARIMAC VARIMAC® VI The Varimac, latest in MAC’s line of eddy current comparators gives you fast, convenient sorting of met...

-

MINIMAC® 55 MINIMAC ® 55 With the new Minimac ® 55, you no longer have to sacrifice performance for price. This powerful, ...

-

Eddy Current Testing | ECT - Pengujian dengan arus eddy Inspeksi dengan prinsip Arus Eddy saat ini adalah salah sa...

-

MULTIMAC MULTIMAC ® The versatile new MultiMac ® lets you configure your eddy current test application the way you want – a...

-

Detecting Sigma Phase Download PDF · 2507 Duplex Stainless Steel Tube · 80 FT Cut Lengths · 3/...

-

Hai~ senang bertemu kembali sobat... Di artikel-artikel saya yang sebelumnya, saya menjelaskan mengenai apa sih Non Destructive Testing (...

-

Mengenal Non Destructive Testing Dalam dunia inspeksi atau pengujian pasti sudah banyak yang mengenal kata “ NDT ”, tapi tidak dipung...

-

Inspecting Welded Tube 85 plus years of experience Superior test systems Knowledgeable fieldstaff In or off-line NDT ...

-

More Information Call PT TESTINDO JL. Radin Inten II no. 61 B Duren Sawit, Jakarta 13440 Mobile / WHATSAPP: 0813 9929 1909 PIN BB: ...

-

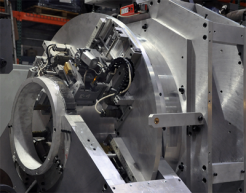

Flux Leakage Inspection Systems FLUX LEAKAGE ROTARIES Magnetic Flux leakage (MFL) non destructive test systems accurate...

Labels

- applications

- Article

- contact us

- demagnetizers

- detecting sigma phase

- echomac

- Eddy Current Inspection Systems

- equipment

- Flux Leakage Inspection Systems

- inspecting billets

- inspecting finned copper tube

- inspecting oil country tubular goods

- inspecting tube ends

- inspecting welded tube

- magnetism detectors

- materials handling & accessories

- minimac® 50

- minimac® 55

- multimac

- multiple & custom ndt system

- production comparator

- rotoflux

- technologies

- ultrasonic test system

- varimac

Blog Archive

-

▼

2016

(21)

-

▼

Januari

(21)

- More Information Call PT TESTINDO JL. Radin Int...

- Inspecting Welded Tube

- Inspecting Tube Ends

- Inspecting Oil Country Tubular Goods

- Inspecting Finned Copper Tube

- Inspecting Billets

- Detecting Sigma Phase

- Demagnetizers

- Varimac

- RotoFlux

- Production Comparator

- Minimac® 55

- Minimac® 50

- Multimac

- Echomac

- Magnetism Detectors

- Materials Handling & Accessories

- Multiple & Custom NDT Systems

- Ultrasonic Test Systems

- Flux Leakage Inspection Systems

- Eddy Current Inspection Systems

-

▼

Januari

(21)

Form

Recent Posts

Download

-

Text Widget

-

Labels

- applications

- Article

- contact us

- demagnetizers

- detecting sigma phase

- echomac

- Eddy Current Inspection Systems

- equipment

- Flux Leakage Inspection Systems

- inspecting billets

- inspecting finned copper tube

- inspecting oil country tubular goods

- inspecting tube ends

- inspecting welded tube

- magnetism detectors

- materials handling & accessories

- minimac® 50

- minimac® 55

- multimac

- multiple & custom ndt system

- production comparator

- rotoflux

- technologies

- ultrasonic test system

- varimac

Copyright ©

Info Non Destructive Testing | Powered by Blogger

0 komentar:

Posting Komentar