PT TESTINDO

JL. Radin Inten II no. 61 B Duren Sawit, Jakarta 13440

Mobile / WHATSAPP: 0813 9929 1909

PIN BB: 580EC93D

Phone. 021-29563045

Fax. 021-29563052

Email: sales@testindo.com

Website: www.testindo.com

Go to Blogger edit html and find these sentences.Now replace these sentences with your own descriptions.This theme is Bloggerized by Lasantha Bandara - Premiumbloggertemplates.com.

Go to Blogger edit html and find these sentences.Now replace these sentences with your own descriptions.This theme is Bloggerized by Lasantha Bandara - Premiumbloggertemplates.com.

Go to Blogger edit html and find these sentences.Now replace these sentences with your own descriptions.This theme is Bloggerized by Lasantha Bandara - Premiumbloggertemplates.com.

Go to Blogger edit html and find these sentences.Now replace these sentences with your own descriptions.This theme is Bloggerized by Lasantha Bandara - Premiumbloggertemplates.com.

Go to Blogger edit html and find these sentences.Now replace these sentences with your own descriptions.This theme is Bloggerized by Lasantha Bandara - Premiumbloggertemplates.com.

|

|

||||||||

| Factors Influencing Test Methods | |||||||||

Some weldline cracks, such as this one shown above, may be detected by both eddy current and ultrasonic equipment. Some weldline cracks, such as this one shown above, may be detected by both eddy current and ultrasonic equipment. |

Factors

that influence system selection include the capabilities and

limitations of each technology, as well as the diameter, wall thickness,

tube condition, and throughput speed of the product under test. Where

the test is applied in the manufacturing cycle also influences the

choice of method and apparatus. This can range from tests limited to the

heat affected zone on the weld mill with perhaps an in-line anneal, to

full body inspection of cut lengths after drawing and annealing or other

heat treating. Each test method has inherent capabilities and

limitations that are different. Factors

that influence system selection include the capabilities and

limitations of each technology, as well as the diameter, wall thickness,

tube condition, and throughput speed of the product under test. Where

the test is applied in the manufacturing cycle also influences the

choice of method and apparatus. This can range from tests limited to the

heat affected zone on the weld mill with perhaps an in-line anneal, to

full body inspection of cut lengths after drawing and annealing or other

heat treating. Each test method has inherent capabilities and

limitations that are different. |

||||||||

|

Common Defects Detected | ||||||||

| Generally, for tube

applications that require high throughput speeds, eddy current is the

preferred method to detect small, short, incomplete welds,and some

subsurface cracks in carbon steel or non ferrous tube. For full body

tests, including the detection of long, continuous defects such as

incomplete seam welds in tube, and inclusions, voids or cavities,

ultrasonic test systems are recommended. Flux leakage systems are

available to accurately detect longitudinal and transverse surface

defects on the OD and ID of heavy-wall magnetic tubing. |

|||||||||

| The picture above shows a short pinhole flaw that was detected by eddy current, but was difficult to detect using ultrasonic tests. | |||||||||

|

Weld Types | ||||||||

| The process of ERW and

Induction welding is preferred for most carbon and alloy steel. Defects

that may arise include all of those previously mentioned. TIG welding is

a slow process usually used for stainless steel or titanium. Incomplete

ID weld defects are a common concern in this process. Laser welding is a

much faster process used for stainless steel, titanium, duplex and

nickel alloys. Typical defects include very short pinholes, and long

continuous ID defects such as incomplete or miss-match welds. |

|||||||||

| This picture above shows a cross section of a tube wall with a long, continuous poor ID weld that was detected by ultrasonic methods, but not by eddy current. | |||||||||

| DOWNLOAD PDF | |||||||||

The Echomac® UT End Tester consists of two

The Echomac® UT End Tester consists of two MAC’s highly trained and knowledgeable engineers, field staff, and

representatives provide superior NDT equipment, services, and training

worldwide.

MAC’s highly trained and knowledgeable engineers, field staff, and

representatives provide superior NDT equipment, services, and training

worldwide.

Download PDF

Download PDF| · 2507 Duplex Stainless Steel Tube

· 80 FT Cut Lengths · 3/4″ OD with .083″ Wall Thickness · Detects Sigma Phase as Small as 2.6% of Tube Wall Cross Section · 2 Channel MultiMac® Eddy Current Tester- Offline · 2 Varimac® Comparator Coils |

The test consists of a 2 channel MultiMac®

coil eddy current tester. 1 channel is used for the detection of

typical defects, while the other channel is used for finding sigma

phase; a condition caused from improper or extensive heat treatment.The second channel on the MultiMac is an absolute tester using two Varimac® coils. One coil is balanced on air and used to calibrate the equipment with a reference standard.

The test consists of a 2 channel MultiMac®

coil eddy current tester. 1 channel is used for the detection of

typical defects, while the other channel is used for finding sigma

phase; a condition caused from improper or extensive heat treatment.The second channel on the MultiMac is an absolute tester using two Varimac® coils. One coil is balanced on air and used to calibrate the equipment with a reference standard.

ual magnetism in the test material after the eddy current test is

ual magnetism in the test material after the eddy current test is The

Varimac, latest in MAC’s line of eddy current comparators gives you

fast, convenient sorting of metal parts such as fasteners, bearings, and

other cold formed pieces. Its high speed continuous operation and

reliability in production environments make 100% non- destructive

inspection economically feasible. It is also used for checking alloy and

hardness in bar or wire.

The

Varimac, latest in MAC’s line of eddy current comparators gives you

fast, convenient sorting of metal parts such as fasteners, bearings, and

other cold formed pieces. Its high speed continuous operation and

reliability in production environments make 100% non- destructive

inspection economically feasible. It is also used for checking alloy and

hardness in bar or wire.

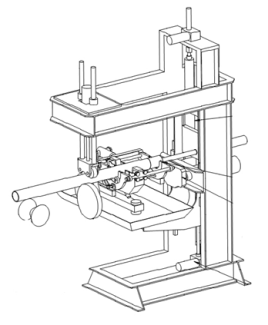

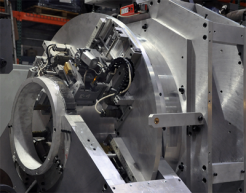

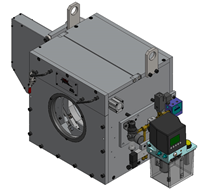

FLUX LEAKAGE ROTARIES

FLUX LEAKAGE ROTARIES The electronics are capable of differentiating between ID and OD

defects, using a unique multiprobe feature which allows convenient

operation at greater speed. A flux measurement circuit is included to

indicate whether the test piece is properly saturated. To detect

longitudinal defects, the material under test is driven through rotating

headplates that include transverse magnetizing coils and test probes.MAC also offers Rotoflux systems

to detect transverse defects where the magnetizing poles are placed in a

fixed position perpendicular to the axis of the material under test,

and the sensors are rotated around the test piece.

The electronics are capable of differentiating between ID and OD

defects, using a unique multiprobe feature which allows convenient

operation at greater speed. A flux measurement circuit is included to

indicate whether the test piece is properly saturated. To detect

longitudinal defects, the material under test is driven through rotating

headplates that include transverse magnetizing coils and test probes.MAC also offers Rotoflux systems

to detect transverse defects where the magnetizing poles are placed in a

fixed position perpendicular to the axis of the material under test,

and the sensors are rotated around the test piece. A single frequency Windows®

computer based nondestructive test instrument that uses low frequency

electromagnetic techniques to inspect magnetic materials for variations

in physical characteristics such as alloy, heat treatment and case

depth. Highly selective gating circuit permits it to discriminate

between changes in the signal’s phase, amplitude or harmonic distortion

from the fundamental frequency to its 13th order harmonic. The

instrument also features a unique display (vector or lissajou) that

provides simultaneous display of the standard, acceptable piece and the

test piece wave forms for easy comparison. Setup and monitor on site or

through a computer network.

A single frequency Windows®

computer based nondestructive test instrument that uses low frequency

electromagnetic techniques to inspect magnetic materials for variations

in physical characteristics such as alloy, heat treatment and case

depth. Highly selective gating circuit permits it to discriminate

between changes in the signal’s phase, amplitude or harmonic distortion

from the fundamental frequency to its 13th order harmonic. The

instrument also features a unique display (vector or lissajou) that

provides simultaneous display of the standard, acceptable piece and the

test piece wave forms for easy comparison. Setup and monitor on site or

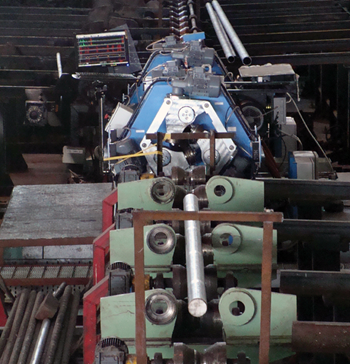

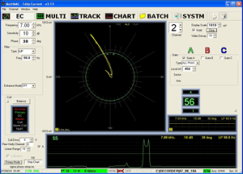

through a computer network. MULTIMAC®

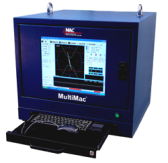

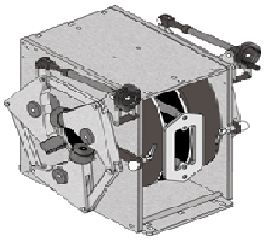

MULTIMAC® The MultiMac® SM is a high speed, computer with Windows®

Operating System and MAC’s latest proprietary software. The instrument

is packaged in a compact cabinet that includes a built-in touch screen

monitor and may also be operated with a keyboard or mouse. The output

connectors are included for an optional external monitor.With these features, MultiMac® SM can operate on a wide variety of non-magnetic products, or use Direct Current saturation systems to inspect magnetic material.The

system has a broad test frequency selection from 1KHz to 5MHz. Test

speeds can range from one foot per minute up to several thousand.

Installation can be in-line or at a separate test station.MultiMac®

SM has up to 4 test channels that can operate at the same or different

frequencies for special applications. The main test display provides all

the information needed to set up and operate MultiMac® SM.

Polar and linear signal traces can be simultaneously displayed, along

with all test parameters. User configurable reports containing customer

and product information in addition to defect location, time, amplitude

and phase can be stored locally or on a network server.

The MultiMac® SM is a high speed, computer with Windows®

Operating System and MAC’s latest proprietary software. The instrument

is packaged in a compact cabinet that includes a built-in touch screen

monitor and may also be operated with a keyboard or mouse. The output

connectors are included for an optional external monitor.With these features, MultiMac® SM can operate on a wide variety of non-magnetic products, or use Direct Current saturation systems to inspect magnetic material.The

system has a broad test frequency selection from 1KHz to 5MHz. Test

speeds can range from one foot per minute up to several thousand.

Installation can be in-line or at a separate test station.MultiMac®

SM has up to 4 test channels that can operate at the same or different

frequencies for special applications. The main test display provides all

the information needed to set up and operate MultiMac® SM.

Polar and linear signal traces can be simultaneously displayed, along

with all test parameters. User configurable reports containing customer

and product information in addition to defect location, time, amplitude

and phase can be stored locally or on a network server. ECHOMAC® ROTARY

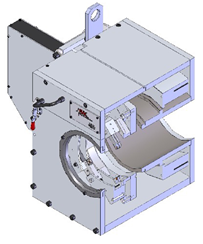

ECHOMAC® ROTARY ECHOMAC® FD-5

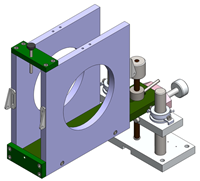

ECHOMAC® FD-5 Where rotating

eddy current probes are being used, they are housed in a rotary

headplate, mounted in rotary mechanics that include a motor for spinning

the headplate with its test prob

Where rotating

eddy current probes are being used, they are housed in a rotary

headplate, mounted in rotary mechanics that include a motor for spinning

the headplate with its test prob

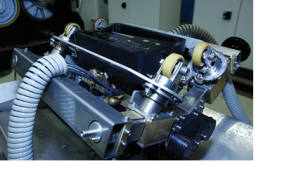

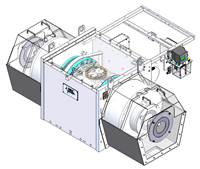

Rotary Mechanics for Ultrasonic Systems

Rotary Mechanics for Ultrasonic Systems ECHOMAC® Rotary Ultrasonic System Rotating ultrasonic transducers are

available for shear-wave configuration (surface and subsurface defects)

and compression-wave configuration (internal defects and dimensional

measurements such as wall thickness.) Models are available for

inspecting material from 10 mm to 360 mm in diameter at test speeds up

to 200 fpm, depending on the size and condition of the material. Rotary

ultrasonic systems can be combined with eddy-current instrumentation to

meet API, ASTM, Mill, and Customer specifications.

ECHOMAC® Rotary Ultrasonic System Rotating ultrasonic transducers are

available for shear-wave configuration (surface and subsurface defects)

and compression-wave configuration (internal defects and dimensional

measurements such as wall thickness.) Models are available for

inspecting material from 10 mm to 360 mm in diameter at test speeds up

to 200 fpm, depending on the size and condition of the material. Rotary

ultrasonic systems can be combined with eddy-current instrumentation to

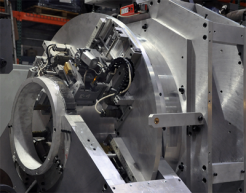

meet API, ASTM, Mill, and Customer specifications. The

Echomac FD-5 is a computer based ultrasonic inspection instrument

designed for on or off-line flaw detection, thickness and outside

diameter measurement. Instead of using common spike pulsers, the FD-5

uses negative square pulsers lower in amplitude and longer in length

coupled with a pitch-catch through transmission to fully optimize

transducer efficiency. Building on the success and wide acceptance of

the Echomac FD-4, the FD-5 achieves a new level of improved signal to

noise, repeatability and reliability. Improved 16 steps damping

adjustments in increments of 20 Ohms, instead of the common 2 step high

or low adjustment, allows the transducer to detect lower signals while

giving the user better control over reflections. With a higher gain

range and the addition of 5 low pass filters and 5 high pass filters,

noise is significantly

The

Echomac FD-5 is a computer based ultrasonic inspection instrument

designed for on or off-line flaw detection, thickness and outside

diameter measurement. Instead of using common spike pulsers, the FD-5

uses negative square pulsers lower in amplitude and longer in length

coupled with a pitch-catch through transmission to fully optimize

transducer efficiency. Building on the success and wide acceptance of

the Echomac FD-4, the FD-5 achieves a new level of improved signal to

noise, repeatability and reliability. Improved 16 steps damping

adjustments in increments of 20 Ohms, instead of the common 2 step high

or low adjustment, allows the transducer to detect lower signals while

giving the user better control over reflections. With a higher gain

range and the addition of 5 low pass filters and 5 high pass filters,

noise is significantly FLUX LEAKAGE ROTARIES

FLUX LEAKAGE ROTARIES

In encircling/sector coil technology,

In encircling/sector coil technology,